Baselectron - Some interesting numbers

Some interesting numbers to understand who Baselectron really are:

Every year approximately

2000 new codes

An establishment

located on 1,300 sqm

Six hundred microns

our highest track

Seventy-five microns

our thinnest track

Over forty years of experience at your service

Twenty

employees

Twenty-five millimeters our

thickest printed circuit

Six and a half meters the longest pcb flex that we have printed

Six drilling machines

at our disposal

Three Cam Station

in our establishment

Almost two and a half meters the longest rigid circuit that we have printed

"Two steps"

the strangest circuit

A laboratory for metallographic and chemical analysis

A tenth of a millimetre our thinnest printed circuit

Note:

The printed circuits are also called differently depending on their characteristics, for example:

Single sided

Monolayer and Single side are different ways to identify a printed circuit with a single side or with a single layer of tracks.

Double sided

Double side and bilayer there are different ways to identify a printed circuit with dual sides or with the tracks on both surfaces.

Multilayer

Multilayer MLB are the names that are used to identify multilayer printed circuits with additional layers of internal tracks.

Solder

Solder resist or solder mask is what is called the usually green protective layer that limits the welding to only the pads and also leaves the comb connectors and mechanical contacts uncovered, it is often shortened to solder.

Some useful information on printed circuits produced by Baselectron:

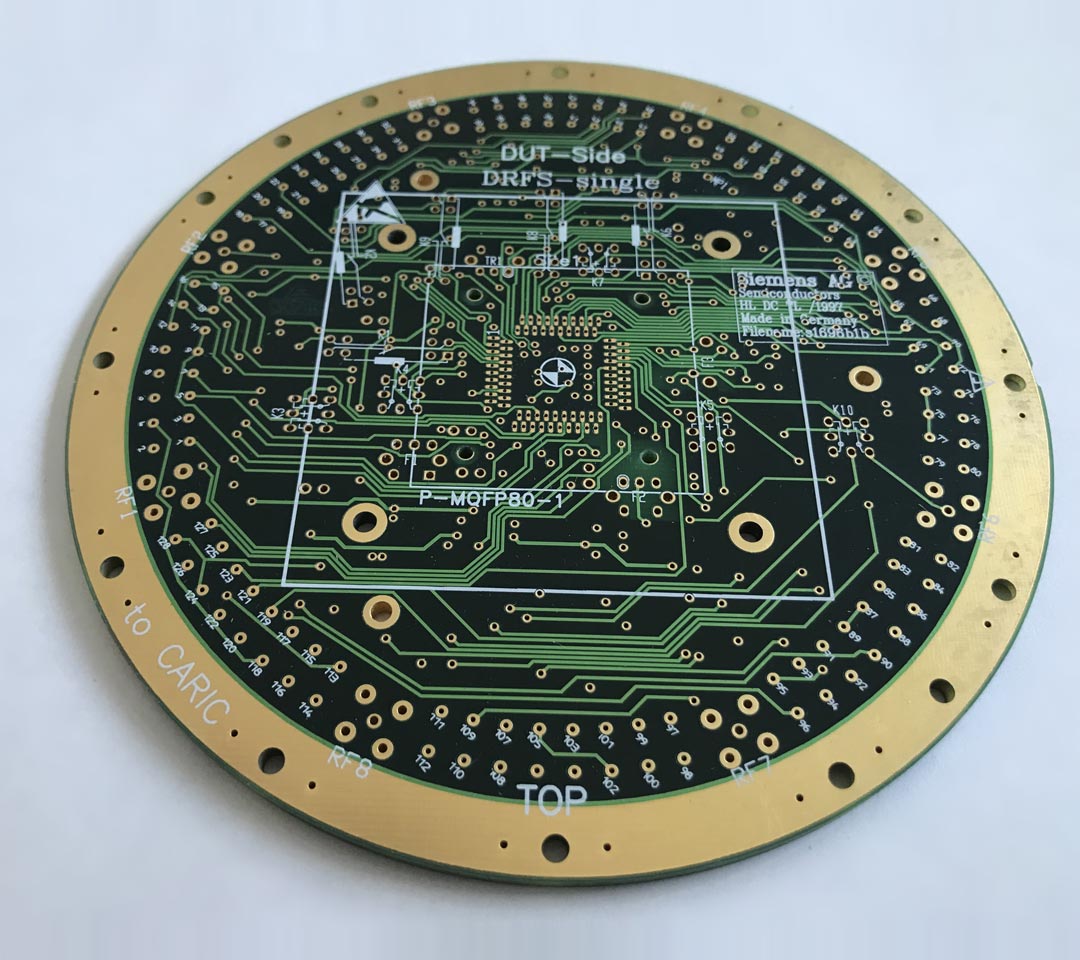

Printed circuits

Printed circuits are no longer simple supports on which to assemble the electronic components: today they are true and proper electronic components that contributes actively to the good functioning of the apparatus. Just think for example that to ensure the integrity of the signals at high speed, the tracks of a printed circuit must ensure an extremely constant controlled impedance, as in the case of pcbs made on FR4, Teflon, ceramic with an accurate sizing control; instead, in other cases a printed circuit behaves as a heat sink, contributing decisively to keeping the junction temperature of the power components low.

In Baselectron we are able to produce PCBS on aluminium, Metalcore and AlluFless (a technique that allows to provide a flexible printed circuit board with flexible connections); in more than forty years of activity in the field of printed circuits, we have acquired a vast experience and expertise on special materials, that allows us to propose ourselves as a partner in the engineering phase of the printed circuit board.

Prototypes and samples

The production of samples and prototypes of printed circuits is our corporate mission. Printed circuits being the main component of electronic equipment, firstly, they must be available and dealt with rapidly: in some cases, we can even produce them in a single day.

In a world that continues to move faster and faster, Baselectron’s urgent printed circuit samples, offers that extra possibility to meet the needs of the most demanding of customers. Baselectron’s prototypes, samples and the pre -production of printed circuits of are all produced on the same lines dedicated also to the series production, therefore guaranteeing high-quality standards. .

Production of printed circuits

Our offer is to assist our customer from the samples, to the set of printed circuits: in addition to our production plants (which include all phases of implementation of the PCBS), we are able to meet any requirement in terms of timing, quality and price, thanks also to the collaboration of our qualified Asian partners. With this organisation, we can pass from the samples to a production of large series of printed circuits, without additional costs for tooling.

Our productions of printed circuits are UL listed and are guaranteed and certified by TUV quality system. We are available to tackle any problems related to the production of the series and the assembly during the development phase of the printed circuit board, in such a way as to contribute to implement suitable choices to minimise production costs of the electronic equipment.